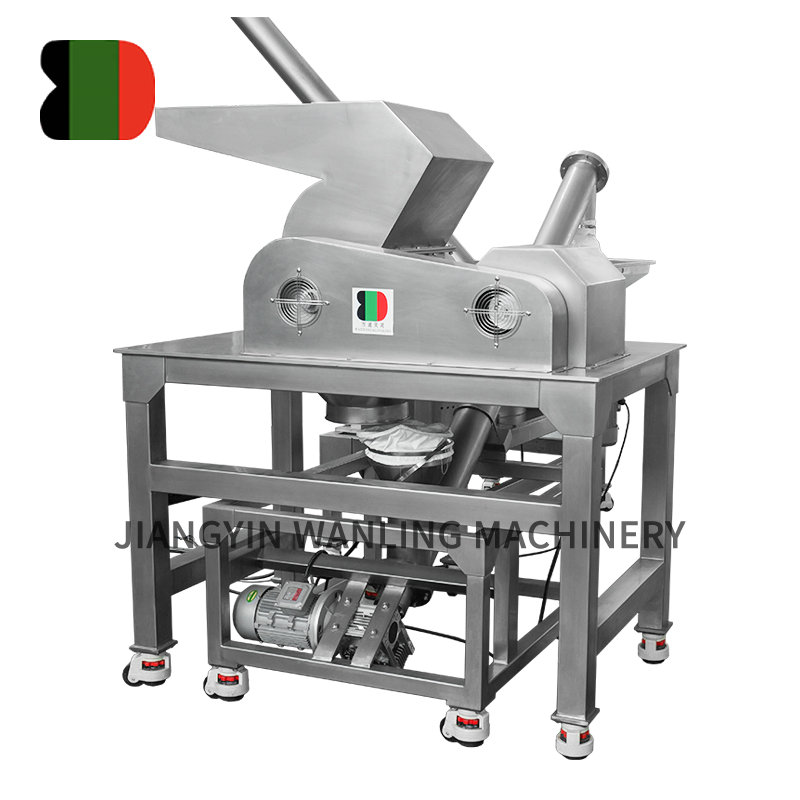

Coarse crusher is a widely used mechanical equipment in various industrial sectors, primarily designed to crush raw materials into the desired particle size and shape. As an indispensable part of production lines, coarse crushers play a crucial role in many industries.

In the mining industry, coarse crushers play a key role. During the extraction and processing of ores, coarse crushers are extensively used to crush raw ores into suitable particle sizes for subsequent beneficiation processes. Through the action of coarse crushers, raw ores can be processed more effectively, thereby enhancing production efficiency and ore utilization.

Coarse crushers also play an important role in the construction materials industry. In the process of construction, a large amount of aggregates and crushed stones are required for concrete preparation, road construction, and other projects. Coarse crushers can crush various raw materials such as stones and ores to obtain aggregates that meet the requirements, providing essential material support for construction projects.

Coarse crushers are vital in the waste management industry. Waste management poses a significant challenge in modern society, and coarse crushers can crush various waste materials such as plastics, metals, and wood, making them easier to store, transport, and recycle. This helps reduce environmental pollution and resource waste.

Coarse crushers also find wide applications. In the cultivation and processing of crops, certain raw materials such as corn stalks and straw need to be crushed for purposes like feed preparation and soil improvement. Coarse crushers can effectively crush these raw materials into the desired particle sizes, improving their utilization efficiency and value.

To ensure the normal operation and prolong the service life of coarse crushers, regular lubrication and maintenance are essential. Lubrication maintenance is crucial for the normal operation of coarse crushers, as it can reduce the wear of machine parts, decrease operating noise, improve production efficiency, and extend equipment life.

Regular inspection of the lubrication system of coarse crushers is necessary to ensure smooth lubricant supply. Lubricating oil plays a crucial role in lubrication and sealing, effectively reducing friction between parts, decreasing energy consumption, and prolonging the service life of machines. Therefore, it is essential to ensure the quality of lubricating oil and replace it timely according to usage conditions.

Regular cleaning and replacement of lubrication components are required. During operation, coarse crushers generate a large amount of dust and impurities. If not cleaned promptly, lubrication components may get clogged, affecting lubrication efficiency. Therefore, regular cleaning of lubrication components and timely replacement based on wear conditions are necessary to ensure proper operation.

Regular inspection of various components of coarse crushers is essential to ensure their normal operation. This includes inspection of bearings, gears, belts, and other components. Any issues found should be repaired or replaced promptly to prevent equipment downtime and production delays.

Coarse crushers are important crushing equipment widely used in various industrial sectors. Regular lubrication maintenance can ensure the normal operation of coarse crushers, improve production efficiency, prolong equipment service life, and provide guarantee for stable production lines.

Español

Español