Achieving high-precision measurement in powder packaging machines mainly relies on the following technologies and design elements:

Measuring Devices and Sensors:

Powder packaging machines are typically equipped with measuring devices, such as electronic scales, which use electronic sensors to monitor the weight of the powder material in real-time, ensuring packaging accuracy. Electronic scales offer high precision and automated control advantages, significantly improving packaging accuracy. Advanced models may also employ high-precision weight sensors and feedback control systems that continuously measure and adjust to ensure each package contains the exact amount of powder.

Powder Flow Control:

The flowability of powders can vary, so advanced flow control technologies, such as variable frequency drives or pneumatic regulators, are used to ensure a stable and controllable powder flow, thereby enhancing packaging accuracy.

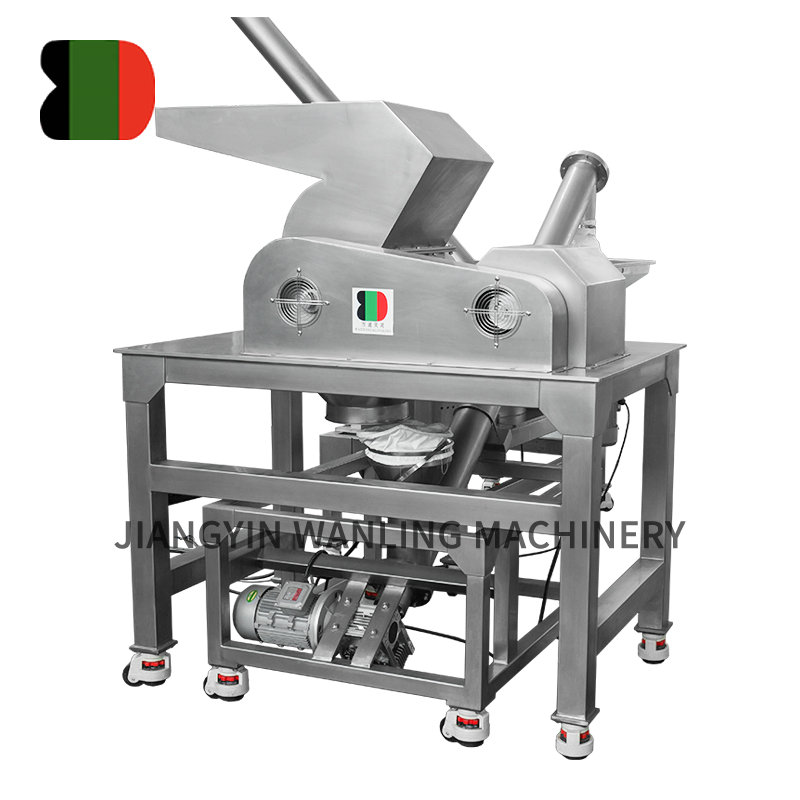

Powder Dispensing System:

Precision dispensing systems, such as rotary valves or vibrators, ensure that powder flows uniformly into the packaging container, preventing uneven weight distribution. Some packaging machines use screw conveyors, where the rotating screw blades move the powder from the storage bin to the working position of the packaging machine, ensuring uniform and stable material supply.

Powder Compression and Vibration:

During the packaging process, powders may form voids or bubbles, affecting accuracy. To address this issue, some machines employ compression or vibration techniques to compact the powder, ensuring consistent volume in each package.

Automatic Correction and Calibration:

Modern automatic packaging machines are often equipped with automatic correction and calibration functions, which can detect and correct any deviations during the packaging process, such as material supply fluctuations or packaging material misalignment, to maintain high precision.

Precision Control Software:

These machines typically come with sophisticated control software that allows precise adjustment of various parameters, such as packaging speed, sealing temperature, and measuring weight, to accommodate the characteristics and packaging requirements of different powders.

Screw Design and Material Characteristics Adaptation:

In screw design, ensuring that the volume of each pitch is consistent is key to enhancing precision. This requires precise machining during the manufacturing of the screw feeders to guarantee their volumetric measurement performance. Selecting the appropriate screw diameter, pitch, and core diameter based on the packaging specifications and bulk density of the material improves accuracy. For materials with higher bulk density, a smaller screw diameter may be needed to achieve greater precision.

Achieving high-precision measurement in powder packaging machines primarily relies on advanced measuring devices, flow control technologies, dispensing systems, compression and vibration techniques, automatic correction and calibration functions, precision control software, and adapting screw design to material characteristics. The combined application of these technologies and designs ensures that powder packaging machines can achieve high-precision measurement during the packaging process, meeting the needs of various industries and materials.

Español

Español